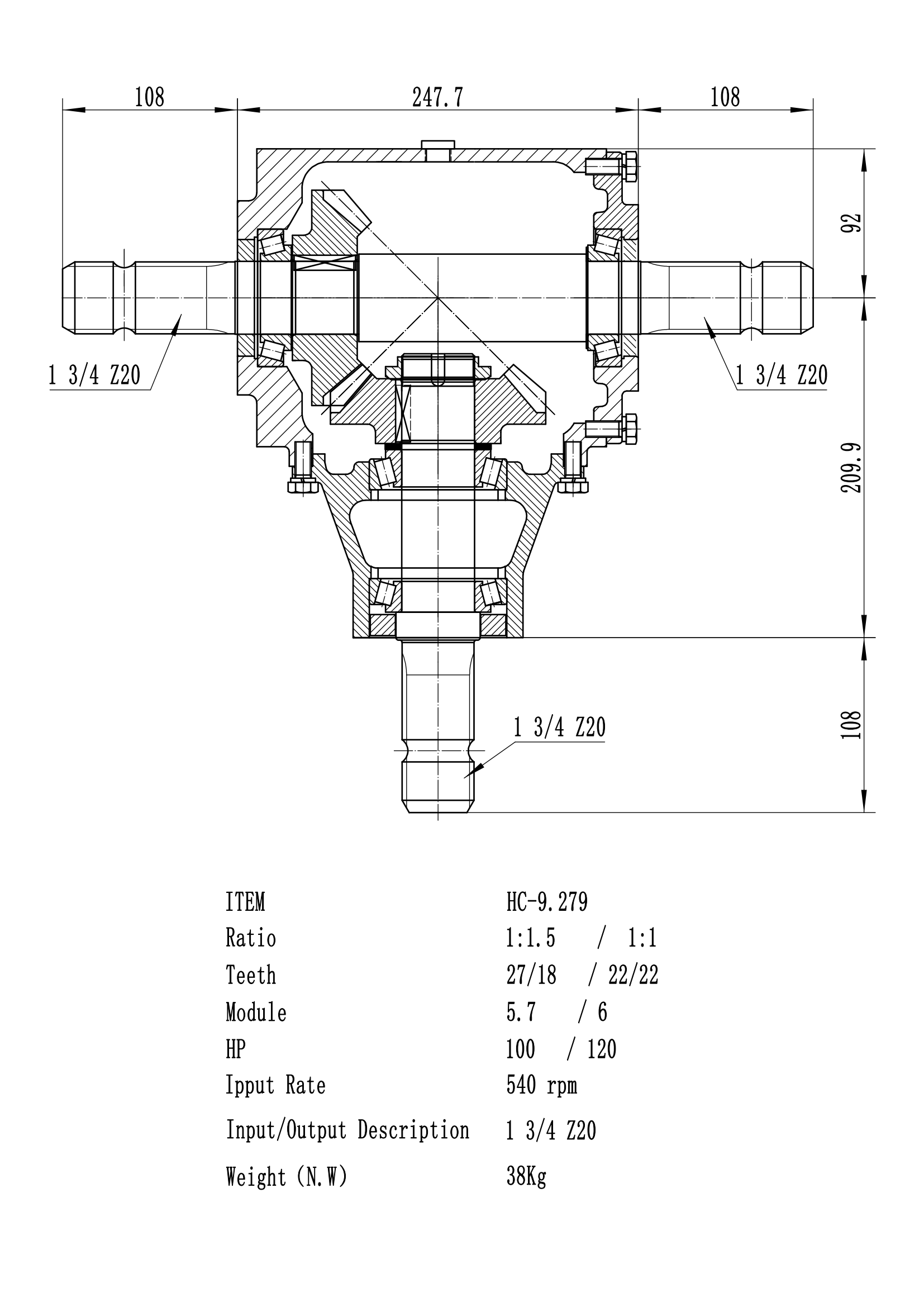

Product drawing

Fertilizer Spreader Gearbox

The input shaft is connected to the tractor's power take-off (PTO), which generates rotational power, while the output shaft is connected to the blades of the rotary tiller. To transmit the power generated by the PTO to the blades, the gears within the gearbox have been carefully designed to mesh smoothly and efficiently.

Fertilizer Spreader Gearbox Wholesale

Bearings reduce friction and wear and extend gearbox life by supporting the gears and output shaft. Seals are fitted around the shaft to prevent the ingress of dirt and contaminants that could cause damage and loss of efficiency.

Fertilizer Spreader Gearbox

In addition to regular maintenance, such as changing the gearbox oil and checking for wear, some gearboxes have other features that help to improve performance and durability. For example, to help dissipate heat quickly and ensure the gearbox does not overheat, some rotary cutter gearboxes are fitted with cooling fins. Other transmissions are equipped with slipper clutches designed to protect the transmission from damage caused by sudden high loads. In summary, the gearbox of a rotary mower is a key component of a rotary mower that is designed to perform a wide range of agricultural tasks. It is made from high quality materials to withstand the stresses and strains of cutting. Regular maintenance is essential to ensure efficient and reliable operation, while additional features can improve performance and extend the life of the gearbox.

Response Efficiency

1. How long is your production lead time?

It depends on product and order qty. Normally, it takes us 15 days for an order with MOQ qty.

2. When can I get the quotation?

We usually quote you within 24 hours after we get your inquiry. If you are very urgent to get the quotation, please call us or tell us in your mail, so that we could regard your inquiry priority.

3. Can you send products to my country?

Sure, we can. If you have no your own ship forwarder, we can help you.

About samples

1. How to send samples?

You got two options:

(1)You can inform us your detailed address, telephone number, consignee and any express account you have.

(2) We have been cooperated with FedEx for more than ten years, we have good discount since we're theirs VIP. We'll let them estimate the freight for you, and the samples will be delivered after we received sample freight cost.